I-QGF120 rinser/filler/capper monobloc sisixhobo esiphuhliswe kwisiseko sobuchwephesha obuphambili bamazwe ngamazwe ngokweendlela zesantya esiphezulu kunye nophuhliso oluzenzekelayo lwesiselo eTshayina.

Iimpawu eziphambili

1) Esi sixhobo sinesakhiwo esitsha, itekhnoloji ephucukileyo, umsebenzi othembekileyo, ukuhamba kobuchwephesha besayensi, ucoceko olulungileyo kunye ne-automation ephezulu. Utyando lulula. Sesona sixhobo sifanelekileyo sokuzalisa zonke iibhotile zamanzi.

2) Yamkela iibhotile ezininzi phezulu nasezantsi ukwenza iibhotile ezi-1 phezulu naphantsi ngaxeshanye ukuphucula ukusebenza kakuhle kwemveliso.

3) Ukukhethwa kwezinto eziphathekayo kunengqiqo. Uninzi lwamalungu amkela intsimbi ekumgangatho ophezulu ephuma kumazwe angaphandle. Amanye amalungu asebenzisa izinto ezingeyotyhefu nezihlala ixesha elide.

I-4) Uninzi lwezixhobo zinokufakelwa kwaye zilungiswe ngezixhobo eziqhelekileyo, ezilungele ukuba umntu wogcino atshintshe kwaye alungise.

5) Inokhuseleko olugqibeleleyo lokhuseleko. Ngelixa ucinezela ukumisa iswitshi yongxamiseko, umatshini awunakuqalwa, kwaye ulondolozo kunye nedosi yezinto ekrwada kunokwenziwa ngalo mzuzu.

6) Ibhotile phezulu nasezantsi ukuxhobisa indawo yokuhlola ukukhusela umatshini ngokufanelekileyo.

7) I-Cap sorter ixhobisa ukufumanisa ukunqongophala kwe-cap ukulawula ukuqala kunye nokuyeka kwe-cap unscrambler.

8) Uqhagamshelo lwebhodlela ukuya phezulu nasezantsi kunye nesidluliseli sesixhobo sokuhlanjululwa kwenziwa kwindawo esemgangathweni ukuthintela impembelelo yebhotile eyaliweyo.

9) Ukulungelelaniswa kwezixhobo eziphambili zokuqhuba kunye nekhonkco kunokwenziwa ngokuqhaqha isigqubuthelo xa umatshini uyeka. Faka isiciko xa uhlengahlengiso lugqityiwe.

I-10) Inkqubo yomgca we-pneumatic ixhobisa ivalve yokunciphisa uxinzelelo ukuze ivumelane nayo yonke ingcinezelo yomoya.

I-11) Ukuhambisa ibhotile yamkela intsimbi engenasici esicaba-phezulu ukunqanda ukubhukuqwa kwebhotile.

I-12) Yamkela ikhabhinethi yokulawula umbane yensimbi engenasici. Yonke inkqubo yokusebenza njengebhotile phezulu, ukuhlanjululwa kwebhotile, ibhotile phantsi kunye nokuzaliswa kulawulwa yi-PLC.

13) Amacandelo ombane aphambili (i-frequency converter, i-PLC, i-photoelectric switches, i-relay) yamkele i-MITSUBISHI, i-OMRON, njl.

I-14) Inkqubo yomgca we-Pneumatic atopts imveliso ye-AirTAC, njl.

Inkcazo ngokubanzi

1) Isiseko somatshini siqulunqwe ngepleyiti yensimbi engenasici kunye nepayipi yensimbi engenasici. Ineenzuzo zokuqina okuphezulu, ukuqina okuhle, ubunzima obulula, ukubonakala okuhle, ukujonga okuhle kunye nokucoca ngokulula.

I-2) Indlela yokulayisha ibhotile ithatha i-90 ° cylinder yokuguqula indlela, izinzileyo kwaye inokwethenjelwa.

3) Ukutyisa ibhotile kunye nendlela yokutyhala yenziwe ngentsimbi yokutyhala ibhotile kunye nesilinda sokutyhala ibhotile. Umsebenzi wayo kukutyhala iibhotile kwi-bottle-n conveyor kwi-hopper yokulayisha ibhotile.

Umgaqo wokuSebenza

Iibhotile ezingenanto zithunyelwa kwi-conveyor yokulayisha ibhotile ukusuka kwibhotile-kwi-conveyor. Emva kokuba iibhotile zichukumise umtshini wokuhamba kwi-conveyor yokulayisha ibhotile, i-PLC yenza umsebenzi wokubala. Xa kubalwa iibhotile ezi-1 sele zilungile, isilinda sokutyisa ibhotile kunye nesixhobo sokutyhala sisebenza ukutyhala intonga yokutyhala ibhotile ukutyhala iibhotile ezingenanto kwisixhobo sokuhambisa ibhotile ukuya kwihopha yokulayisha ibhotile. Ibhotile ithe tye kwi-hopper kwaye i-bottle loading sensor sensor ibona ukuba ibhotile kwi-hopper sele ilungile kwaye ithumela umqondiso ngokukhawuleza ukwenza ibhotile yokubhukuqa i-cylinder isenzo sokutyhala ibhotile yokulayisha i-hopper ijika i-90 ° kwaye iguqule ibhotile kwindawo yezinga. . Ngeli xesha, umlomo webhotile ujonge kwicala elichanekileyo lekomityi yokulungisa ibhotile yesihambisi sesihlambi. I-bottle pushing & loading sensor ibona ukuba ibhotile sele ilungile kwaye ibhotile ityhala kunye nokubamba izenzo ze-cylinder ukutyhala ibhotile kwikomityi yokulungisa yokuhambisa i-rinser kwaye iqonde inqanaba lokulayisha iibhotile. Isixhobo sokuhambisa amanzi siqhutywa sisixhobo sokuqhuba kwaye iibhotile ezingenanto ziya phambili kumzimba womatshini.

Inkcazo ngokubanzi

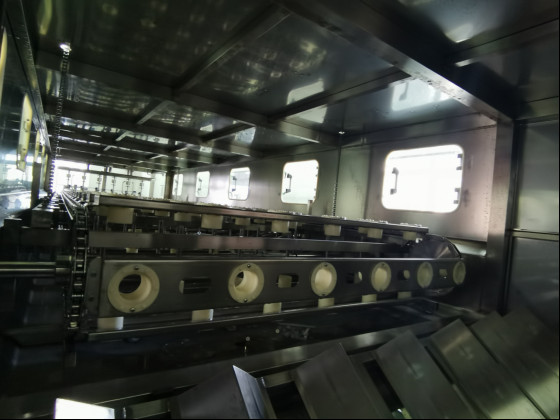

1) Isiseko se-rinser sidityaniswe nge-bended steel stainless plate kunye ne-stainless steel pipe pipe. Ineenzuzo zokubukeka okuhle, ukuqina okuphezulu, ukuqina okuhle, ubunzima obulula kunye nokucoca ngokulula.

2) Isixhobo sokuhambisa i-riser yenziwe nge-sprocket esebenzayo kunye ne-passive, ikhonkco, ipleyiti yokubamba ibhotile kunye nekomityi yokulungisa ibhotile. Ikhonkco kunye ne-sprocket ziyilwe kakuhle ukuzenza zenzululwazi ngakumbi kwaye zigqibelele.

3) Isixhobo sokuqhuba seriser sityhalwa sisilinda ukwenza ibhotile kwindawo nganye yokusebenza ihlale ixesha elithile. Ikhonkco ibalwa ngokungqongqo ngokulayishwa kwebhotile ngokuzenzekelayo kunye neendawo zokulahla ukuze kuqinisekiswe indawo echanekileyo yokuqhuba okuzenzekelayo.

Umgaqo wokuSebenza

Xa ibhotile ingena kwikomityi yokulungisa i-rinser conveyor ngesixhobo sokulayisha ibhotile ngokuzenzekelayo, ijaji yoluvo kukho ibhotile kwikhonkco kwaye iqala isilinda esiphambili sokuqhuba ukwenza. Kwangaxeshanye, i-PLC ifumana umqondiso wokwenza impompo yamanzi erecyle, impompo yamanzi e-alkali, impompo yesibulala-ntsholongwane kunye nempompo yamanzi yemveliso iqale ukusebenza. Ibhotile ingena kumvelisi ngamnye ngokuthe ngcembe ukuze ihlanjwe. Irinser ilawulwa yi-PLC. Umjikelo ngamnye wokuhlanjululwa kwetsheyina lokuthomalalisa uya kuhamba kumgama ofanayo ukwenza umlomo webhotile ujongane nentloko yokuhlamba kwindawo nganye yokuhlamba ukuze kuqatshelwe ukusebenza okuhambelanayo kwekomityi yokulungisa ibhotile kunye nomnatha wayo nombhobho wokutshiza. Ngelixa ibhotile igqibezela wonke umjikelo wokuhlanjululwa, i-rinseer conveyor ihambisa ibhotile ecocekileyo kwindawo yokukhupha ibhotile kwaye ibhotile ikwimo yokubeka inqanaba.

Inkcazo ngokubanzi

1) Isiseko sokuzalisa sidityaniswe ngepleyiti yentsimbi egobileyo kunye nombhobho wesquare wentsimbi. Ineenzuzo zokubukeka okuhle, ukuqina okuphezulu, ukuqina okuhle, ubunzima obulula kunye nokucoca ngokulula.

2) I-valve yokuzalisa ithatha intloko entsha yokuzalisa. Ngelixa ugcwalisa, isilinda yenza intshukumo ezantsi, kwaye ukuzalisa iivalvu zemidlalo umzimba uchukumisa umlomo webhotile ukucinezela intwasahlobo kunye nevalve yokuzalisa evulekileyo.

3) I-cap container isetyenziselwa ukugcina kunye nokuthumela i-caps. Xa i-cap sorter ifuna ukongezwa kwe-caps, i-cap elevator ihambisa ii-caps kwisingxobo se-cap esityibilikisa ii-caps ngokuzinzileyo kwaye ngokukhawuleza kwi-cap sorter.

4) ICap sorter yenziwe ikakhulu ngetreyi ejikelezayo, i-cap chute kunye neqokobhe. Umsebenzi wayo kukuzisa iminqwazi yebhokisi kwi-cap chute nge-motor engqukuva yetreyi ejikelezayo kwaye yenze iminqwazi kwi-chute ihle ihle kwaye irenki ngokulandelelana ngendlela ekhethekileyo.

5) Isiseko seCapper sidityaniswe ngeplate yensimbi engenasici kunye nombhobho wesikwere esingenasici. Ineenzuzo zokubukeka okuhle, ukuqina okuphezulu, ukuqina okuhle, ubunzima obulula kunye nokucoca ngokulula.

I-6) Indlela yokufaka i-Capping kukwenza i-capping yebhotile egcweleyo nge-cap ukufezekisa umphumo wokutywina. Yamkela i-pre-cap type capping.

7) Indlela yokuhla ibhotile yenziwe ngehopper yokubamba ibhotile, ibhotile phantsi irack kunye nebhotile phantsi kwesilinda. Ithatha i-90 ° cylinder isakhiwo sokuguqula, izinzile kwaye inokwethenjelwa.

8) Indlela yokutyhalela ebhotileni yenziwe ngepleyiti yokutyhala ibhotile, intsimbi yokutyhala ibhotile kunye nesilinda sokutyhala ibhotile. Ikakhulu yeyokutyhala ibhotile ecocekileyo kwiconveyor.

Umgaqo wokuSebenza

Ibhotile ehlanjululweyo ibhukuqa ngebhotile ephantsi kwendlela kwaye ityhalelwe kwi-filler conveyor kunye ne-filler ngendlela yokutyhala ibhotile, xa i-PLC ifumana umqondiso kwaye ithumela isalathisi sokuqalisa ukuzalisa iivalvu ukwenza ukuzaliswa kwebhotile. Ngelixa iibhotile ezi-4 zigcwele, ibhotile evalekileyo kunye nokubamba i-cylinder ibuyisela kwaye ibhotile iya phambili, emva koko isixhobo sokuxhoma i-cap sixhoma i-cap yebhotile ezaliswe. I-Capping yenziwa xa ibhotile ifika kwisixhobo se-capping. Ibhotile egqityiweyo ithunyelwa kwinkqubo elandelayo ngebhotile-out conveyor.

Iiparamitha eziphambili

| NO | Into | Idatha |

| 1. | Umthamo | 120-150 BPH |

| 2. | Uyilo lwezikhululo zokuhlamba (izikhululo ezi-6 zizonke) | Ixesha le-1 lokukhupha iintsholongwane emanzini ngaphakathi |

| 3. | Ixesha eli-1 lokuvuza | |

| 4. | Ixesha eli-1 lokuhlanjululwa kwamanzi kwakhona | |

| 5. | Imveliso yexesha le-2 yokuhlanjululwa kwamanzi | |

| 6. | Ixesha eli-1 lokuvuza | |

| 7. | Amandla afakiweyo (amandla ewonke) | 3.8KW |

| 8. | Umoya oxinanisiweyo | 0.6m3/min, 0.4 ~ 0.6 MPA |

| 9. | Umoya odibeneyo womoya | φ12 mm |

| 10. | Amanzi okuhlambulula adityaniswe ngaphandle | 8m3/min,0.35~0.5Mpa |

| 11. | Imveliso yokucoca amanzi ngokudibeneyo | φ40 mm |

| 12. | Ukuhlanjululwa konikezelo lwamanzi | φ52 mm |

| 13. | Ukuzalisa amanzi adityaniswe ngaphandle | 15m3/min,0.25~0.3Mp |

| 14. | Ukuzalisa ngokubambisana | φ70mm |

| 15. | Indawo yokukhupha | φ70mm |

| 16. | Ixesha elisebenzayo lokuhlamba | 18sec. |

| 17. | Ubungakanani (mm) | 3550×700×1580 (L*W*H) |

| 18. | Ubunzima | 600 Kg |

-

umatshini wokuzalisa isiselo esithambileyo ngekhabhoni

-

Umatshini wokuzalisa ibhiya yeBotte yeglasi

-

Umatshini wokuzalisa iJusi yebhotile yePET

-

I-Aluminiyam inokuzalisa umatshini wokuzalisa iziselo zeCarbonated

-

Umatshini wokuzalisa ioyile yepiston yohlobo lomgca

-

Umatshini wokuzalisa amanzi ebhotile ye-PET